Molding & Casting

In the past few weeks, we have covered additive and subtractive manufacturing methods. Casting allows us to make an object(s) from the negative of the desired object(s). In comparison with the other digital manufacturing methods, casting and molding have a rich history. It can be dated all the way back to 6000 years ago with an amulet from the Neolithic village of Mehragarh made using the lost wax casting technique.

I was very excited to make a mold as it translates directly into what I want to do for my final project which is to work with mycelium to create bio-friendly products. There are many ways to create moulds, and I did several (3D printed a mold, CNC'd a mold and then used a vacuum former, and used a thermoforming machine) in this page I'll talk about the thermoforming maching.

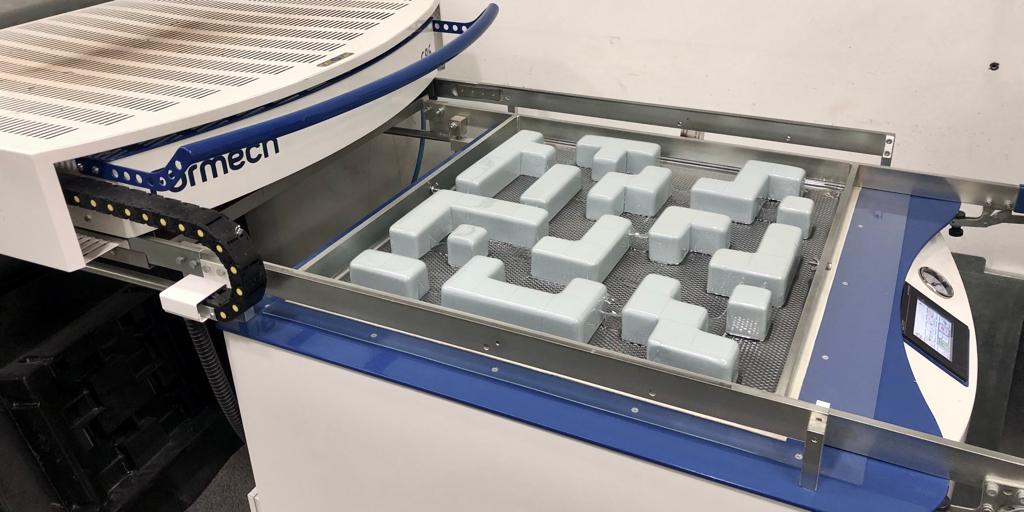

Thermoforming

Thermoforming is a process of heating a thermoplastic sheet to its softening point. The sheet is stretched across a single-sided mold and then manipulated. Then, it cools into the desired shape. We used this mold making machine at ELISAVA alongside some foam blocks that we had cut at the lab.

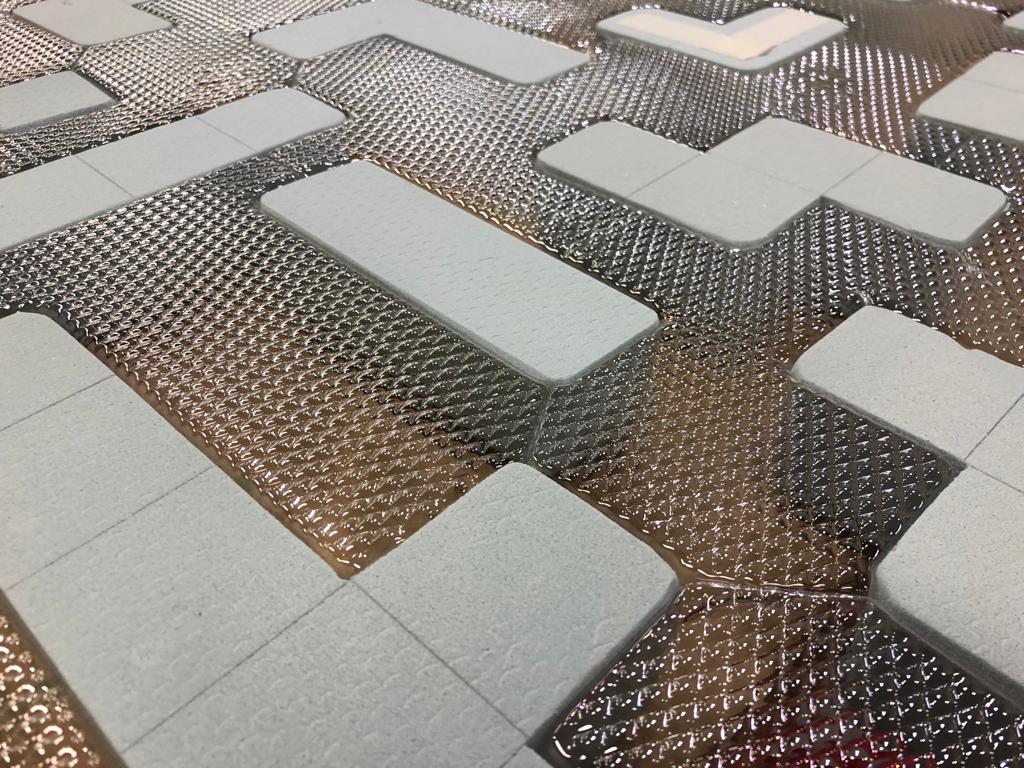

Filling the Molds

Once the plastic sheet molded into the shape of the foam blocks, we grabbed a big bag of grain spawn that had been inoculated with mycelium that we were then going to use to fill up the blocks. The procedure began with us thoroughly sanitising the work station and the molds, we would then break up the mycelium grain into smaller pieces so that we could then stuff them into the molds. Afterwards, we would cover the molds and leave them out of sunlight so that the living fungi could grow into the grain spawn and glue it together.

Final result