Day 1

1. We discussed the broader aspects of the fungal kingdom, their applications, implications, and future possibilities.

2. We talked about fungi’s ability to bio-remediate and did an activity with fungi cards. The students had to read a bit about each myco-remediating fungi species and guess which toxins they are able to decompose.

3. We presented a number of different growing/fabrication techniques and examples of projects done by professionals, students, and myco-enthusiasts.

4. We tasked the students to split up in groups and think of a design and think about what technique they would use to implement the design. As a class, we discussed how the students could implement it as a material for their designs.

Day 2

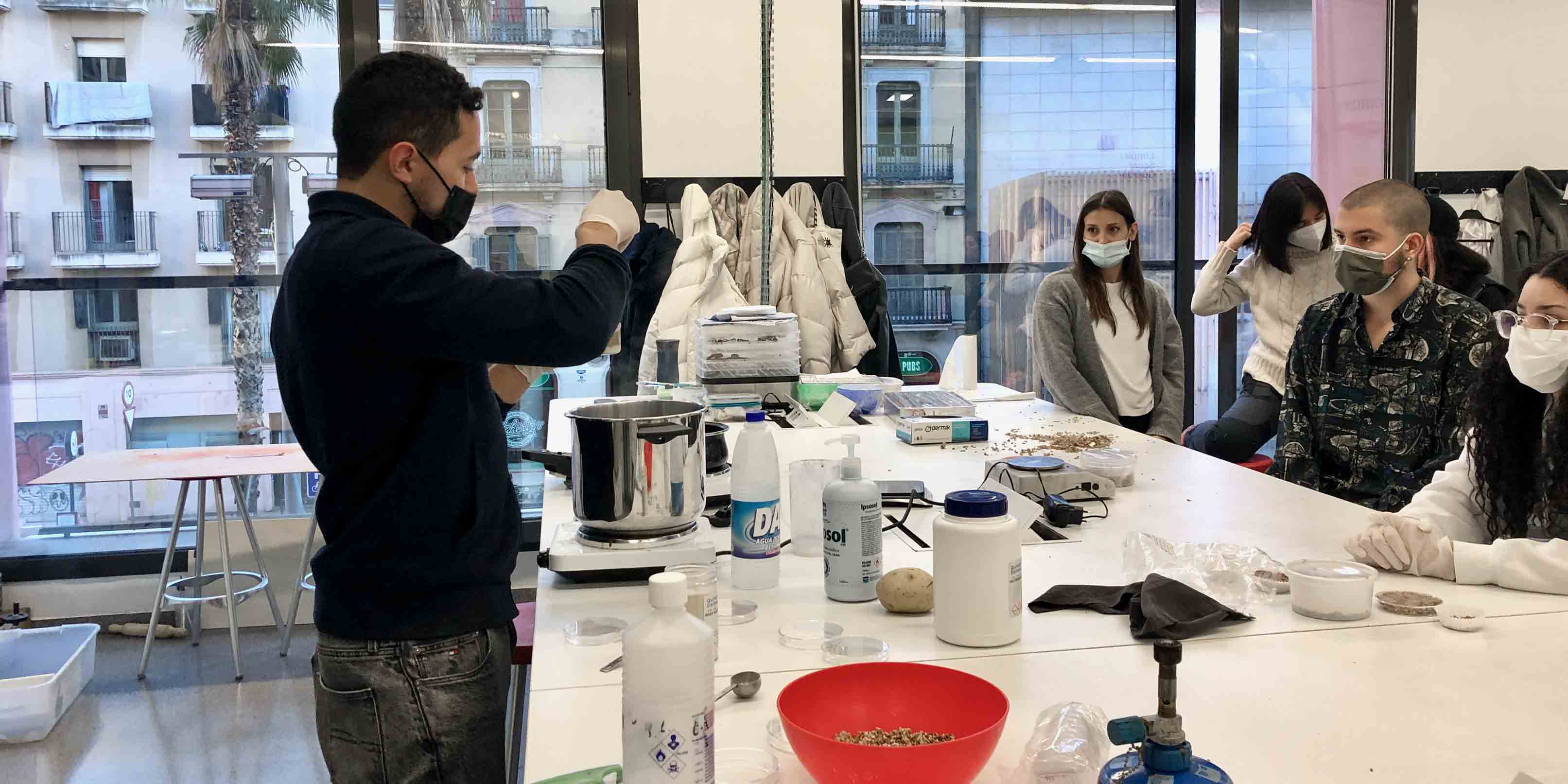

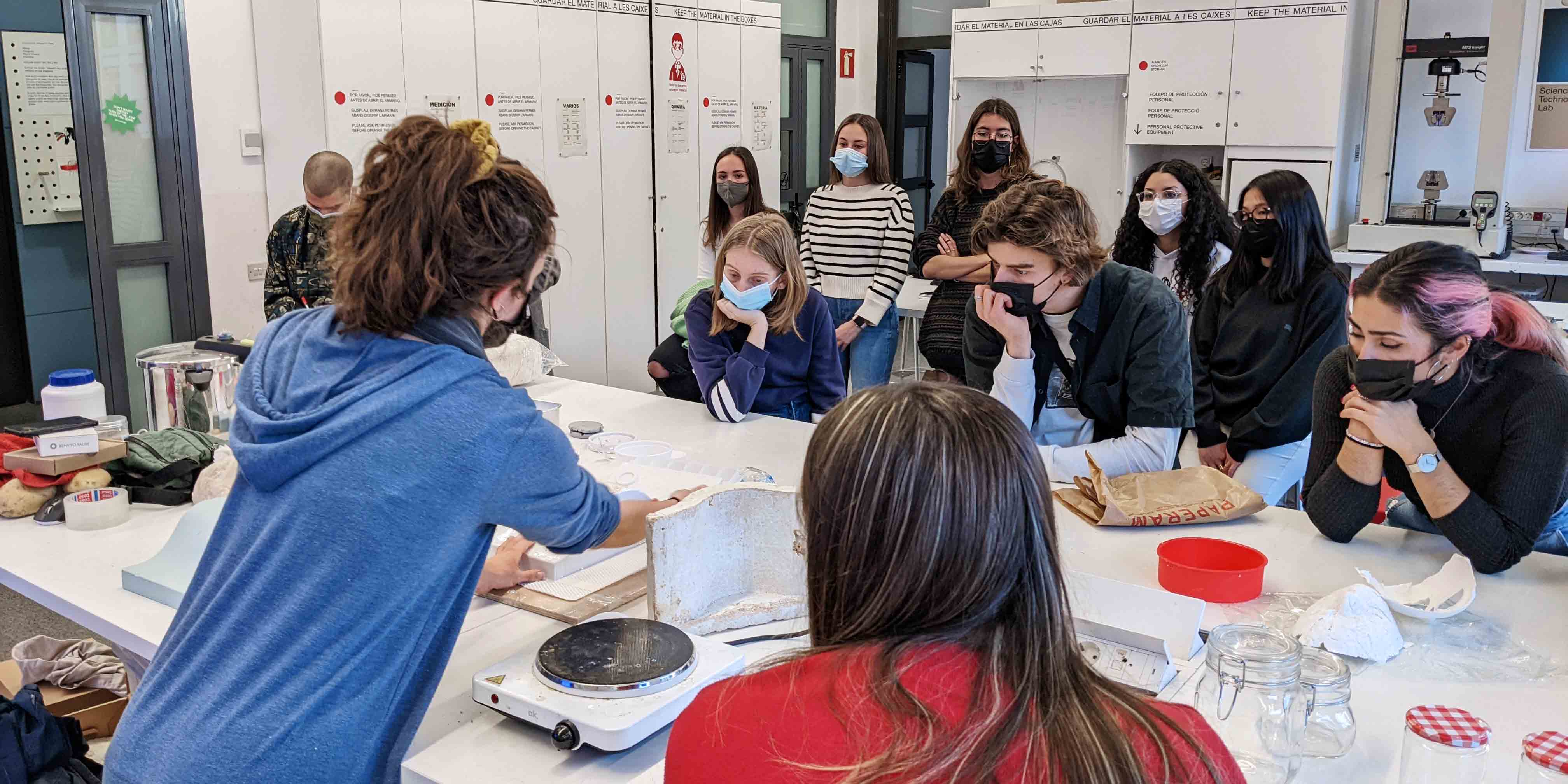

1. Students brought in their own molds and we did a demonstration on how to fill their molds with a substrate (Pleurotus Ostreatus grain spawn). We emphasized the importance of sterilizing the tools and workspace. We included practical details and tips that the students could then carry on to their own projects.

2. We demonstrated how to inoculate a petri dish filled with an agar-starch-dextrose medium with Pleurotus Ostreatus. We explained that we had done this experiment in order to see if the mycelium would decompose pieces of LDPE or OXO biodegradable plastics. This experiment also shows that mycelium can grow on different substrates and can be done without the plastic toxin added.

3. We collected some of the students emails and introduced them to the notion board that we created to share knowledge on the topic of fungi fabrication.

Elisava's communications team published a video of the second day of the workshop on Instagram

https://www.instagram.com/reel/CZrSom1qkEQ/?utm_medium=copy_link

Who were the students?

3rd year Engineering of Industrial Design students who had signed up for this elective course on Mycelium.

The class brief

This year we will experiment with Mycelium simultaneously with a conceptual as well as a hands on approach. The course is structured in two main blocks. During the 4 first weeks of the course the student is encouraged to experiment and to release quick projects without much thought or research; to experiment directly with materials or to quickly mock up rough ideas. Besides the experimental work, the students are conceptually guided by some talks and workshops through a diverse range of social, economic and cultural aspects of the material and the context. In the second bloc, from week 4 to 10, the students should define areas of interest and develop a product from brief to development, prototyping, art direction and communication.

What were the students interested in learning?

The students were very interested in understanding how to fabricate products with mycelium. During the course they would be tasked to create a final product using mycelium. The students were keen to learn about how to combine mycelium with other materials such as textiles and bio-plastics. Some students seemed interested in learning about fungi’s bio-remediating capabilities but were not focused on this area.

What were the students interested in learning?

How can we create flexibility?

How can we alter the color or dye mycelium?

How can we achieve a thin layer of mycelium?

How can we grow mycelium on textiles or mix it with fabrics?

How can we make the mycelium dense and strong?

How can we mix mycelium with bioplastics?

How can we grow pure mycelium or create mycelium “leather”?

We didn’t have time for sufficient preparation and prior communication. When we were offered this opportunity we did not know exactly what expectations the professor had and because it was organized last minute, we only had time to meet with the professor an hour before the class to go over the details. We did not know what mycelium materials she had and we did not have time to order more or different material. The purchased substrate had been out of the fridge for 7 days before we were able to do the demonstration and work with it. This is not ideal because the mycelium was already growing at room temperature for a week and would not grow as well going forward.

We didn’t know much about the students and what they had done in the previous sessions of this course. We found out while speaking with them that they had already received a class on some general information on mycelium and therefore the first part of our class may have been repetitive.

Getting all the materials organized in a very short amount of time was a chaotic. We had to run to buy potatoes and tape at the last minute. Somebody from Elisava had to run and buy Petri dishes for the experiment. We had to change the order of the class on the fly because we didn’t have the right materials.

We have never worked that specific substrate (grain spawn) and we did not know what the result would be. We worked with the substrate in the same way we had worked with the inoculated sawdust substrate from Mycelium Materials Europe.

To sterilize a classroom and tools for 20 different people is very difficult to do.

The students were going to repeat these experiments and so they had lots of specific questions. We didn’t know the answers to everything but we could give educated responses and recommendations.

Because we didn’t not have a lot of time to prepare and we were missing materials we had to think on the fly and come up and were able to adapt the class to the circumstances.

We had done a lot of research before hand and were ready to give recommendations, educated guesses, and related resources. We didn’t know the answer to everything but we did the best that we could.

We were able to show 2 different techniques of how to prepare mycelium mediums/substrates.

We have never worked that specific substrate (grain spawn) and we did not know what the result would be. We worked with the substrate in the same way we had worked with the inoculated sawdust substrate from Mycelium Materials Europe.

The students were very motivated and interested in what we had to share.

At the end of Tuesday’s class, we spoke about the student’s different projects ideas and discussed different fabrication techniques. This discussion was beneficial for all of us to think through all of the diverse ideas and introduce possible fabrication approaches. This challenged us to think about new methods of fabrication depending on the requirements of the applications.

We created a notion board, as a way to create a platform where the students can share resources, links etc. We still filling it with more information and resources but we hope that the students will participate on the platform.

We plan to follow up with Jessica and hopefully visit the class again to see if we can check in with the students on how their projects are going. Jessica and Laura were very welcoming and receptive to this idea.

Improving organization is pertinent. It would make the course easier to teach and allow us to go over more material and answer questions.

We had to think on the fly and think outside of the box, especially when discussing the student’s project ideas.

We had to review and research different fabrication techniques and review the experiments so that we could be ready to explain clearly and answer questions.

We learnt a bit about how to plan and organized the flow of a class.

We would present the professor with a list of materials that we needed a week before the class.

We also would assemble a comprehensive list of questions for the teacher. This might include: what do the students know?; What are they interested in?; What is expected from us?.

We would have made sure that we had a substrate that we were familiar with and stored it in fridge. We would have also bought liquid spores to be able to show the students how to work with them.

I would like to make a deck of fungi cards that present species that are good at growing fast and/or structurally.

We would gather all the materials and setup everything before the class.

We would present more physical samples that exemplify a variety of growing techniques (molds made from different types of substrate, mycelium leather, mycelium grown on textiles, mycelium grown on a bio-plastic etc.)

For the agar-potato-starch-dextrose experiment, we would like to have everyone perform all of the steps from the beginning in groups. This would required more beakers, scales, stoves, etc. We would use glass and metal tools and sanitize them in the pressure cooker.

With better organization, we would spend more time sanitizing our tools and work station so that we could prevent contamination. We could have had more spray bottles with alcohol.

We would like to be able to do the workshop over a longer time frame to allow us to check on mycelial growth and discuss the outcomes with the students.

Laura Benval works with Biofriction.org, the Wetlab in Barcelona, and artists and designers at the Hangar, a collective creative space in Poblenou Nou. She is part of the bio-hacking movement in Barcelona and is well connected with artists and designers that work at the intersection of biology and design. She said that she would be happy to invite to the Hangar to meet some of her colleagues.

Jessica, the professor of the mycelium course is the director of Elisava’s Research department and we hope we can stay in contact with her and could potentially repeat such a workshop for other students at Elisava.

During the course on mycelium, other designers and scientists will be presenting about mycelium. I would like to message Jessica to learn about who these guests are and if there is a possibility to meet them.

I would like to get my hands dirty and start experimenting with different mycelium strains and substrates.

We are hoping to help get the IAAC Biolab up and running soon in order to start doing experiments with different strains of mycelium in petri dishes. We want to do some bio-remediate experiments to identify which strains eat plastic the best. We also want to identify what strains are best for fabrication.

We want to assemble our own substrates and inoculate them. I would like to see if I can use agricultural waste, toxic soils, or bits of plastic the substrate.

I want to try to use recycled textiles as material for molds or to incorporate them in the design. I am interested in designing mycelium products for product design and architectural applications.

Inspired by the Remix the Barrio initiative, we are interested in collecting sawdust and coffee grinds from local businesses in Poblenou to add to the substrate that we want to grow on.

I also want to maintain the notion board and I hope that we can find other myco-enthusiasts who are willing to participate and share knowledge. I am interested to see how this platform will evolve and if people find it useful or not amidst the plethora of other mycology sites and forums on the web.

I have contacted Jessica Dias, who works with Lara Campos. Jessica has been working with mycelium for some time now and we hope that the can learn more about her practice and get inspired by her DIY lab.

Who were the students?

3rd year Engineering of Industrial Design students who had signed up for this elective course on Mycelium.

The class brief

This year we will experiment with Mycelium simultaneously with a conceptual as well as a hands on approach. The course is structured in two main blocks. During the 4 first weeks of the course the student is encouraged to experiment and to release quick projects without much thought or research; to experiment directly with materials or to quickly mock up rough ideas. Besides the experimental work, the students are conceptually guided by some talks and workshops through a diverse range of social, economic and cultural aspects of the material and the context. In the second bloc, from week 4 to 10, the students should define areas of interest and develop a product from brief to development, prototyping, art direction and communication.

What were the students interested in learning?

The students were very interested in understanding how to fabricate products with mycelium. During the course they would be tasked to create a final product using mycelium. The students were keen to learn about how to combine mycelium with other materials such as textiles and bio-plastics. Some students seemed interested in learning about fungi’s bio-remediating capabilities but were not focused on this area.

Which species of fungi can myco-remediate?

Roberto and I dove into scientific articles and found a variety of species that have been found to decompose different toxic materials. After spending a good amount of time researching, I came to the conclusion that surely there are many more species that have this remarkable ability but we simply have not done sufficient research. We found around 20 different species that can bio-remediate different types of toxins. Many researchers are now trying to figure out how to design the ideal environment for the fungi to speed up this process to deal with the scale of our plastic, pesticide, and pollution problems. I assembled a card deck of all of the toxin eating fungi species and during the workshop we set up an activity. On the table lay samples of different types of toxins. We passed out the cards and the participants were tasked to read the bit of information on the card and try to guess which of the toxic samples the fungi species can digest. This deck is downloadable by scanning the QR code to the right. Below, you can see each toxic substrate and their corresponding myco-remediators.